|

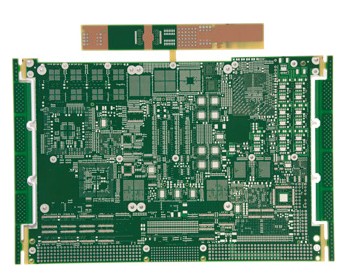

PCB capability:

|

|

|

|

item

|

detail

|

technology material

|

|

1

|

Number of layers

|

1-48 Layers

|

|

2

|

largest size

|

864 x 610 mm (34" x 24")

|

|

3

|

smallest thickness

|

0.2mm (2 layers) / 0.4mm (4 layers) / 0.9mm(8 layers) / 1.2mm (10 layers) / 1.3mm (12 layers) / 1.5mm (14 layers) / 1.7mm (16 layers) / 1.8mm / 2.0 mm (18 layers) / 2.2mm (20 layers) / 2.4mm ( 22 layers) / 2.6mm (24 layers)

|

|

4

|

max. thickness

|

315mil(8mm)

|

|

5

|

max thickness of copper

|

19oz/Inner Layer: 12oz/Outlayers

|

|

6

|

smallest route spacing of inside layer

|

4mil(0.1mm) / 4mil(0.1mm)

|

|

7

|

smallest route spacing of outside layer

|

4mil(0.1mm) / 3.5mil(0.089mm)

|

|

8

|

smallest finished holes

|

6mil(0.15mm)

|

|

9

|

largest aspect ratio

|

12:01

|

|

10

|

smallest through hole and pad

|

via: dia. 0.2mm / pad: dia. 0.4mm ; HDI <0.10mm via

|

|

11

|

smallest tolerances of hole

|

±0.05mm(NPTH), ±0.076mm(PTH)

|

|

12

|

smallest tolerances of finished hold of metal

|

±2mil(0.05mm)

|

|

13

|

smallest tolerances of finished hold of non-metal

|

±1mil(0.025mm)

|

|

14

|

copper thickness of metal hole

|

mini 25um(1.0mil)

|

|

15

|

deviation of hole position

|

±2mil(0.05mm)

|

|

16

|

tolerance of outlook route

|

±4mil(0.1mm)

|

|

17

|

thickness of resistance welding

|

3mil(0.08mm)

|

|

18

|

resistance of isolation

|

1 × 1012Ω

|

|

19

|

thermal shock

|

3 × 10Sec@288 ℃

|

|

20

|

angularity

|

≤0.5%

|

|

21

|

peeling strength

|

1.4N / mm

|

|

22

|

abrasion of resistance welding

|

≥6H

|

|

23

|

grate of inflaming retarding

|

94V - O

|

|

24

|

control of impedance

|

±5%

|

|

25

|

smallest resistance welding window

|

0.05mm(2mil)

|

|

26

|

smallest resistance welding covered

|

0.05mm(2mil)

|

|

27

|

smallest resistance welding bridge

|

0.076mm(3mil)

|

|

28

|

surface arts and crafts

|

Gold plating (electrolytic); Nickel immersion gold (nickel silver); Anti-oxidation; Aluminum (No Aluminum), Spray tin; Halogen-free; Carbon oil;Blue gum; Gold finger (30u''); Silver (3~10u''),Tin (0.6~1.2um),

|

|

29

|

thickness of gold finger

|

0.76um max ( 30u” max )

|

|

30

|

V-cut and V-cut angle

|

30° 45° 60° ,tolerence +/- 5°

|

|

31

|

smallest thickness of V-cut

|

0.8mm

|

|

32

|

tolerance of V-Cut dimension

|

±0.1mm

|

|

33

|

molding method

|

Routing & Punching

|

|

34

|

test voltage

|

±0.1mm(4mil)

|

|

35

|

E-TEST voltage

|

250 ± 5 V

|

|

36

|

production speed

|

60,000 square feet (Month)

|

English

English  Chinese

Chinese You are here:

You are here: